TXRF 310 Fab

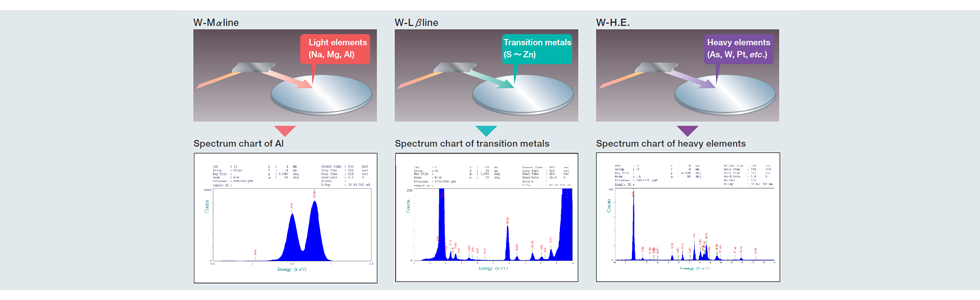

TXRF analysis can gauge contamination in all fab processes, including cleaning, litho, etch, ashing, films, etc. The TXRF-310 can measure elements from Na through U with a single-target, 3-beam X-ray system and a solid-state detector system.

The TXRF-310 includes Rigaku's patented XYθ sample stage system, an in-vacuum wafer robotic transfer system, and new user-friendly windows software. All of these contribute to higher throughput, higher accuracy and precision, and easy routine operation.

Optional Sweeping TXRF software enables mapping of the contaminant distribution over the wafer surface to identify "hot spots" that can be automatically re-measured at higher precision.

Optional ZEE-TXRF capability overcomes the historical 15mm edge exclusion of original TXRF designs, enabling measurements to be made with zero edge exclusion.

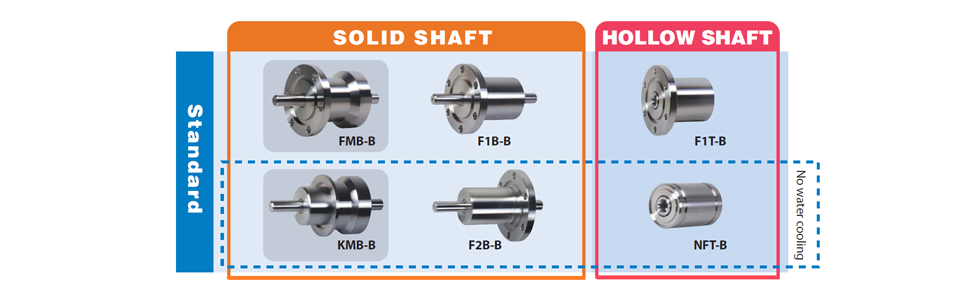

Optional BAC-TXRF capability enables fully-automated front-side and back-side TXRF measurements of 300mm wafers with non-contacting wafer flipping.

Features

- Quick contamination inspection for semiconductor processes

- Accepts 300 mm, 200 mm, and 150 mm wafers

- Wide range of analytical elements (Na~U)

- Light-element sensitivity (for Na, Mg, and Al)

- Single target 3-beam method and XYθ stage are unique to Rigaku, enabling highly accurate ultra trace analysis over the entire wafer surface

- Import measurement coordinates from defect inspection tools for follow-up analysis

- FOUP, SMIF, and through-the-wall configurations are available to meet the various needs of high-volume manufacturing wafer fabs